MoldGrfx

mold modification for embedding patterns or graphics in your product.

A novel coating technology for diffractive decoration of plastic products. Decoration. Differentiation. Counterfeit Protection

MoldGrfx allows differentiation of plastic products and serves as counterfeit protection in electronics, devices, consumables, fashion, etc. in hidden or visible positions. MoldGrfx works on common types of thermoplastic and rubber materials and can be used with any transparent, tinted or pigmented plastic

How does it work?

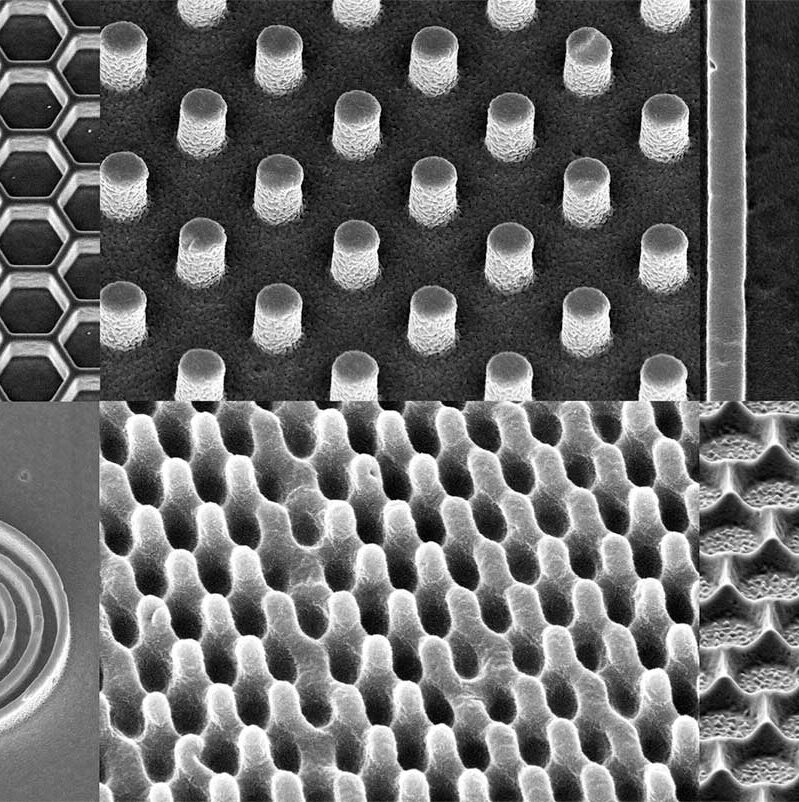

1. Mastering

We add submicron surface structures to your design

Designing master size up to: 22 x 26 mm

Minimum feature size: 10 µm

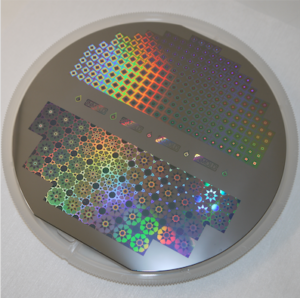

2. Scale Up

Step up the logo or design to a larger area.

Mastering production is offered within MoldGrfx Services in a state-of-the-art class 100 cleanroom. The step up up area: 10 x 10 mm

3. Transfer to Mold

We transfer your design to your mold insert for your production.

A coating in the range of nm size is added. The tolerances of your mold will not be affected.